Sulapac’s Circulytics Scorecard Published: A+ in Innovation

CirculyticsTM, a novel circularity metrics developed by the Ellen MacArthur Foundation (EMF), looks beyond products and material flows. It is designed to assess a company’s circularity performance in a holistic way. As an EMF network member Sulapac participated in testing Circulytics together with over 30 other companies. Here we present and discuss our scorecard based on the first published version of the assessment tool.

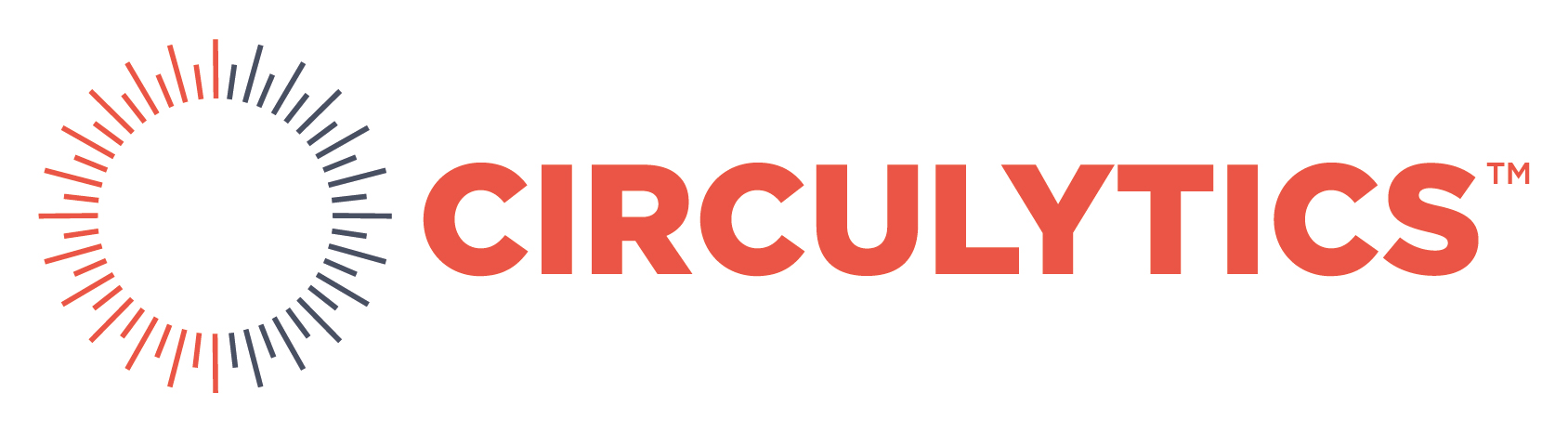

Circulytics was built to help companies take their circularity efforts to the next level by assessing their entire operations. It includes altogether seven indicators divided into two main categories: ‘enablers’ and ‘outcomes’. All the indicators are assessed separately based on the data provided by the company*. The scale is similar to the grading system in the US schools ranging from A (best) to E. The overall score is the average of ‘enablers’ and ‘outcomes’ scores. As the number of companies using Circulytics increases, EMF will calculate and provide the industry average for the users for benchmarking their result within their own sector.

“We are proud of the fact that four out of the five ‘Enablers’ scores start with A. The ‘A+’ score in ‘innovation’ gives credit for Sulapac’s Research and development function, which is dedicated for creating safe and circular alternatives to conventional fossil-based plastics”, says Maija Pohjakallio, Sustainability Director of Sulapac.

Sulapac’s Circulytics scorecard based on data submitted by the company in Q1 2020.

*EMF does not validate the submitted data, nor does it endorse companies which have received a score card.

Holistic approach and continuous improvement

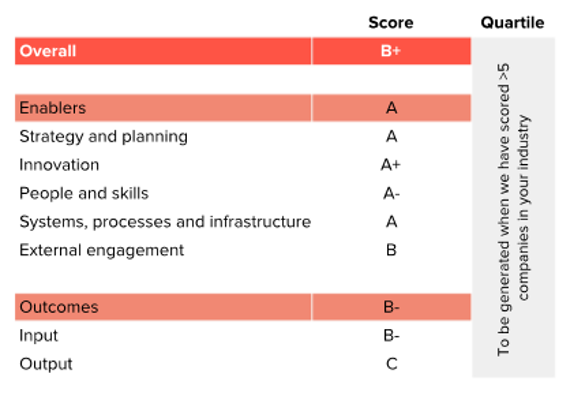

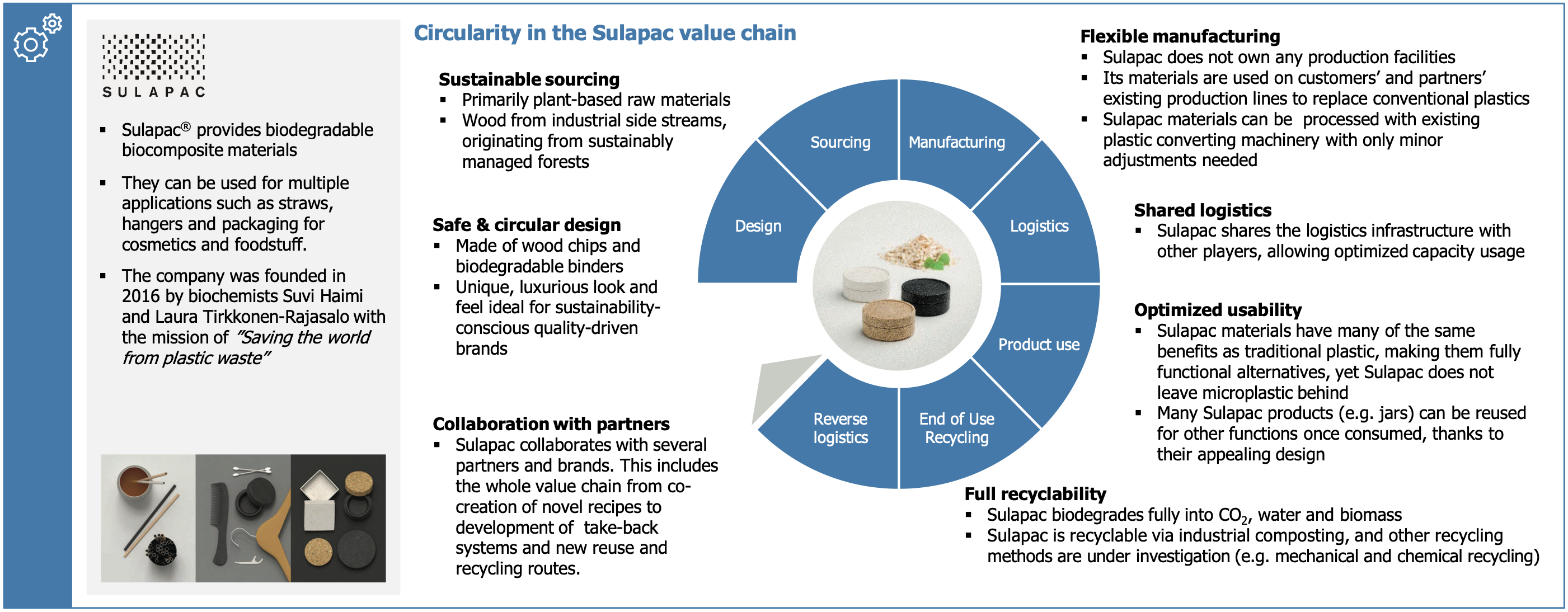

The scores reflect our holistic approach. Even though Sulapac is a small company, we find it important not only to bring novel sustainable materials to the market but also to be active in awareness raising and education, and in driving collaboration between stakeholders. Our business model is based on partnerships, factory as a service concept, meaning we don’t own any production facilities but partner with existing production plants, and material sales combined with consultative support throughout the product life cycle. Our materials are used on customers’ and partners’ existing production lines to replace conventional plastics. This business model already enables localized manufacturing of the end-products, and as our business grows, also the material production can be taken close to the customer. Our aim is to use local, nearby raw materials, as much as possible.

Circularity is rooted deep in Sulapac’s operations – from R&D to end-of-life recycling. Image from publication Sustainable and Circular Business Models for the Chemical Industry, by the Chemical Industry Federation of Finland, Business Finland and Sitra, in cooperation with Accenture.

Some of the input data related to production originates from the different suppliers and partners in our network. As Sulapac is a startup company in a scaling up phase, our portfolio and networks are constantly expanding. Thus, our sourcing and production processes are in a dynamic state and under constant optimization, which means that we don’t have precise static data on all input parameters. For example, the energy mix of transportation and production differ between the actors in the network. The output result depends on e.g. the available data on recycling rates. As a young company, we haven’t yet collected data on the recycling rates of postconsumer Sulapac waste, which lowers our output score.

To secure effective recycling in the future, we are investigating additional recycling methods and actively participating in discussions with relevant stakeholders to get the required infrastructure and policies in place for Sulapac and other biomaterials to reach their full circular potential.

“Sulapac is committed to continuous improvement in its circularity performance. Scaling up and optimizing the production with carefully selected partners with sustainability and circularity as priorities is likely to improve the input and output results. In May 2020 we received the ISO14001 Environmental Management Certification, which also highlights continuous improvement”, Pohjakallio outlines.

Circular economy necessitates novel metrics

Companies play an important role in the transition towards a more circular economy. A systemic change is needed, which is why the metrics too need to be holistic in nature. “To guide the transition, we must integrate the aspects of technologies, environment, business models and co-operation”, Pohjakallio explains. Circulytics promotes the view that circular economy encompasses much more than improved material management & recycling and reducing the negative impacts of linear production.“

Pohjakallio warmly welcomes tools like Circulytics to complete the conventional environmental metrics such as life cycle analysis (LCA). “I am already looking forward to the next level of metrics which would extend the analysis to positive handprints of the company on its customers and other stakeholders”, Pohjakallio concludes.

Circulytics is available free of charge to all interested companies at ellenmacarthurfoundation.org.

Sulapac accelerates and inspires the plastic waste-free future with sustainable materials that are beautiful and functional. Like nature. The Helsinki-based company was founded in 2016 and has been ranked one of the 100 hottest startups in Europe by WIRED UK. sulapac.com