Eco-safe Sulapac straw inspired by nature

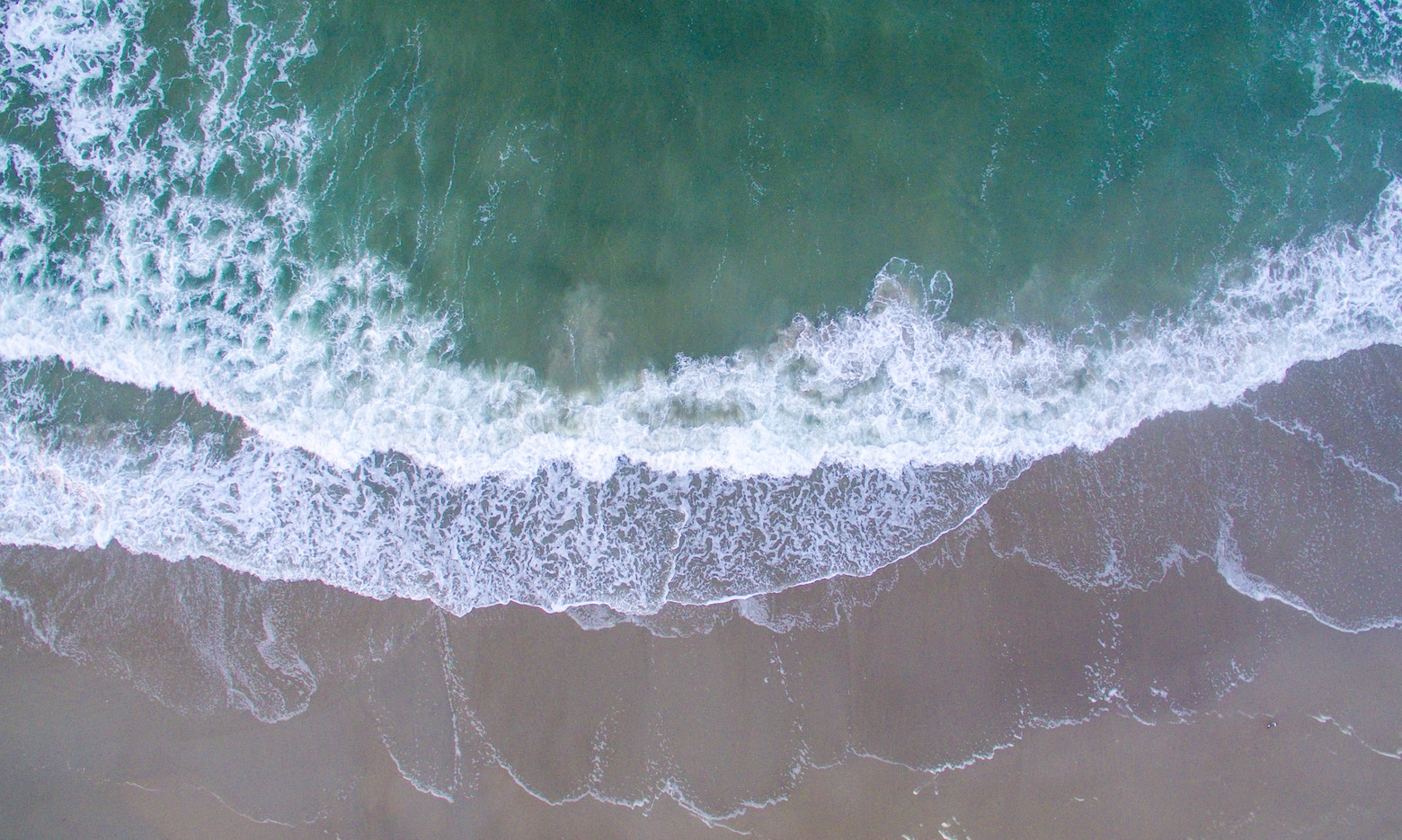

Eight million tons of plastic leak into the oceans annually. If nothing changes the weight of plastic in oceans will rival that of fish by 2050. This is no longer a challenge, but a crisis which calls for immediate solutions.

Our core competence at Sulapac is to innovate novel wood-based materials that are microplastic-free. By the end of the year 2019 we’ll introduce to the market our newest product, the ocean safe Sulapac Straw. The straw has been designed to mimic nature. Its main components are wood dust and plant-based binders, and it biodegrades fully into CO2, water and biomass, even in marine environment, within a similar time frame as tree leaves in nature. Various tree leaves have shown to disintegrate and biodegrade in nature in 0,5-4 years depending on the tree species and the environment.

No time to lose

Currently, there is no international standard providing clear pass/fail criteria for the degradation of polymeric materials in sea water. The standardization work is in progress (ISO TC61/SC14/WG2), but as the plastics crisis is on, we can’t afford to wait until all the related standards and definitions are in place. This might take years, whereas the plastic crisis requires concrete actions today. To the best of our knowledge, the comparison of the biodegradation of the Sulapac Straw to that of naturally occurring biomaterials, such as tree leaves, combined with the ecotoxity tests as specified in the European Standard EN 13432 for compostability, provides scientifically sound criteria to state that the Sulapac Straw is ocean safe.

We have chosen ASTM D6691*) as the laboratory test method for the biodegradation of the Sulapac Straw. In this test the sample is in powdered form in natural sea water and the CO2 production during biodegradation is measured as a function of time. In addition to ASTM D6691, we have collaborated with marine biologists who have performed field tests in open Baltic sea water. Both test types suggest that the Sulapac Straw biodegrades at a similar speed as tree leaves in nature (assuming that the biodegradation of the Sulapac Straw occurs with a constant rate).

We are actively following the development of the regulatory field and standards and have decided to refer to the Sulapac Straw as ocean safe, instead of marine biodegradable, at least until there is a consensus on standards and definitions. Moreover, the term biodegradable is often confused with ‘biobased’ and ‘oxo-biodegradable’, and therefore, we try to avoid using the word ‘biodegradable’ when possible.

*) Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials in the Marine Environment by a Defined Microbial Consortium or Natural Sea Water Inoculum

Free from microplastic pollution

By the expression ocean safe we also want to highlight that biodegradability is an inherent product characteristic, not a guidance to throw the item into nature after use. All waste, no matter of which material, must be properly managed. The Sulapac Straw is industrially compostable according to the European Standard EN 13432. In the tackle against plastic waste, sustainable and smart consumption is equally important, so only take a straw if you really need one!

As all other biopolymers, such as collagen and native cellulose, Sulapac disintegrates first into tiny particles. However, after disintegration the Sulapac particles biodegrade fully into CO2, water and biomass in open environments, meaning that Sulapac is a microplastic-free material as it does not accumulate in the nature. In contrast, if traditional plastics end up in nature, either in the form of microplastics or visible litter, they are very persistent and stay there for hundreds of years. In the course of time this means accumulation, which can lead to collection of harmful chemicals or pathogens capable of enriching along the food chain.

There is a sense of urgency to promote sustainable and microplastic-free production and consumption. Cleaning the oceans from microplastics is even more difficult than cleaning them from macroscopic plastic waste.

If you are interested in buying Sulapac straws, click here.

Sulapac® is a wood-based material innovation inspired by Nordic nature. It is a lot like plastic, yet it biodegrades fully leaving no microplastics behind. As a premium material that is safe and circular by design, Sulapac is ideal for quality driven brands with genuine commitment to sustainability. Plastic product manufacturers can use Sulapac® with their existing machinery, making sustainability an easy choice. The company was founded in 2016 and is based in Helsinki, Finland. Sulapac has been ranked one of the 100 hottest startups in Europe by WIRED UK both in 2018 and 2019. Join our mission to save the world from plastic waste! sulapac.com