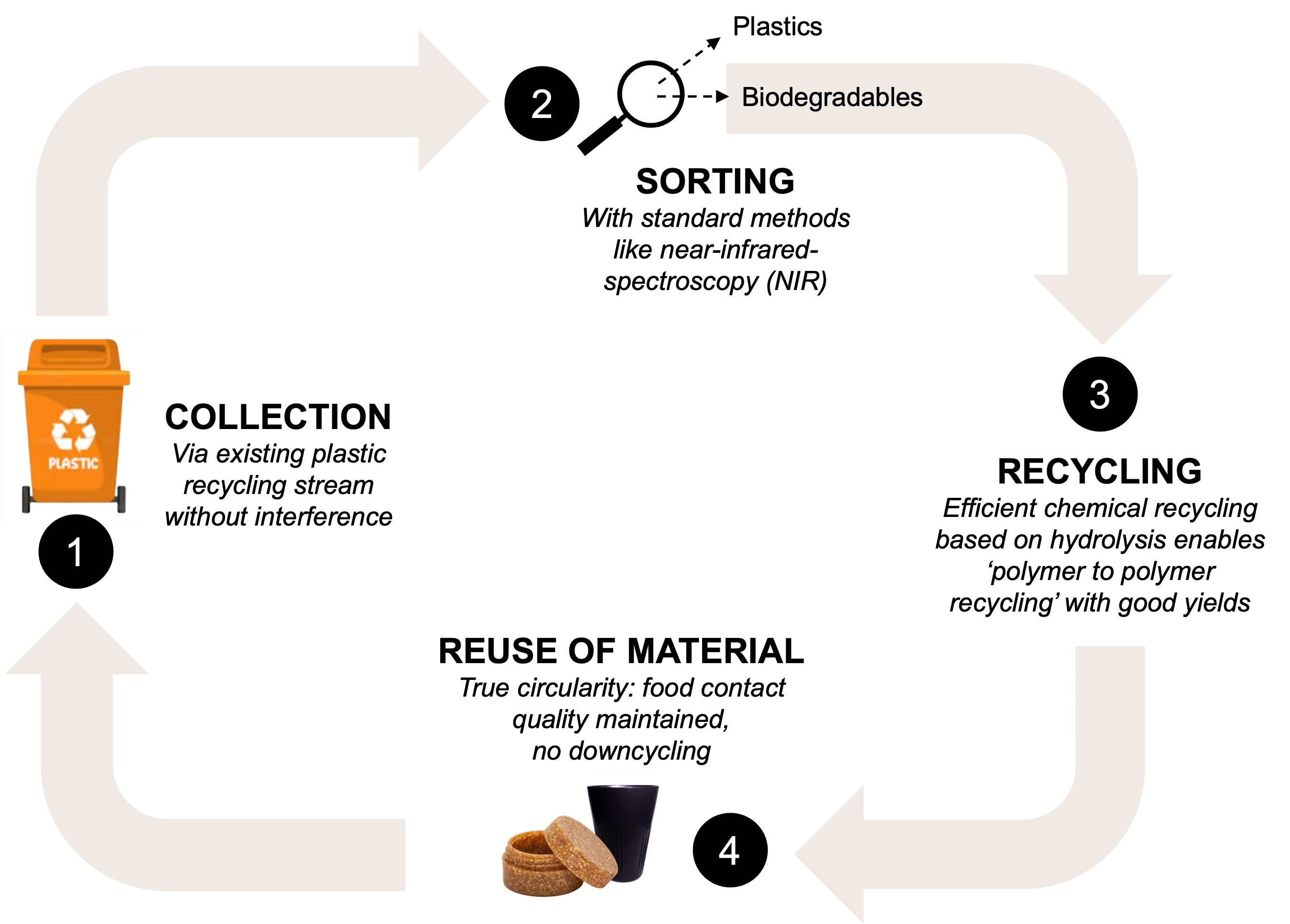

Sulapac materials are designed to be recycled either mechanically or chemically. Once a product can no longer be reused or repurposed, recycling is the recommended end-of-life option for our materials. And, recycling biobased biodegradable materials in general, is the key to truly sustainable circular bioeconomy. So, let’s dig deeper into the topic!

Most Sulapac materials can be recycled in a so called polymer-to-polymer process, where polymers are broken down back to monomers via hydrolysis. Those monomers are then used as building blocks for new biopolymers. This process has numerous benefits: the yields are high, energy consumption low, and most importantly, the quality and purity of the recycled material is the same as for virgin material.