Breakthrough in bio-composite recycling: from post-consumer waste into lactic acid – at scale

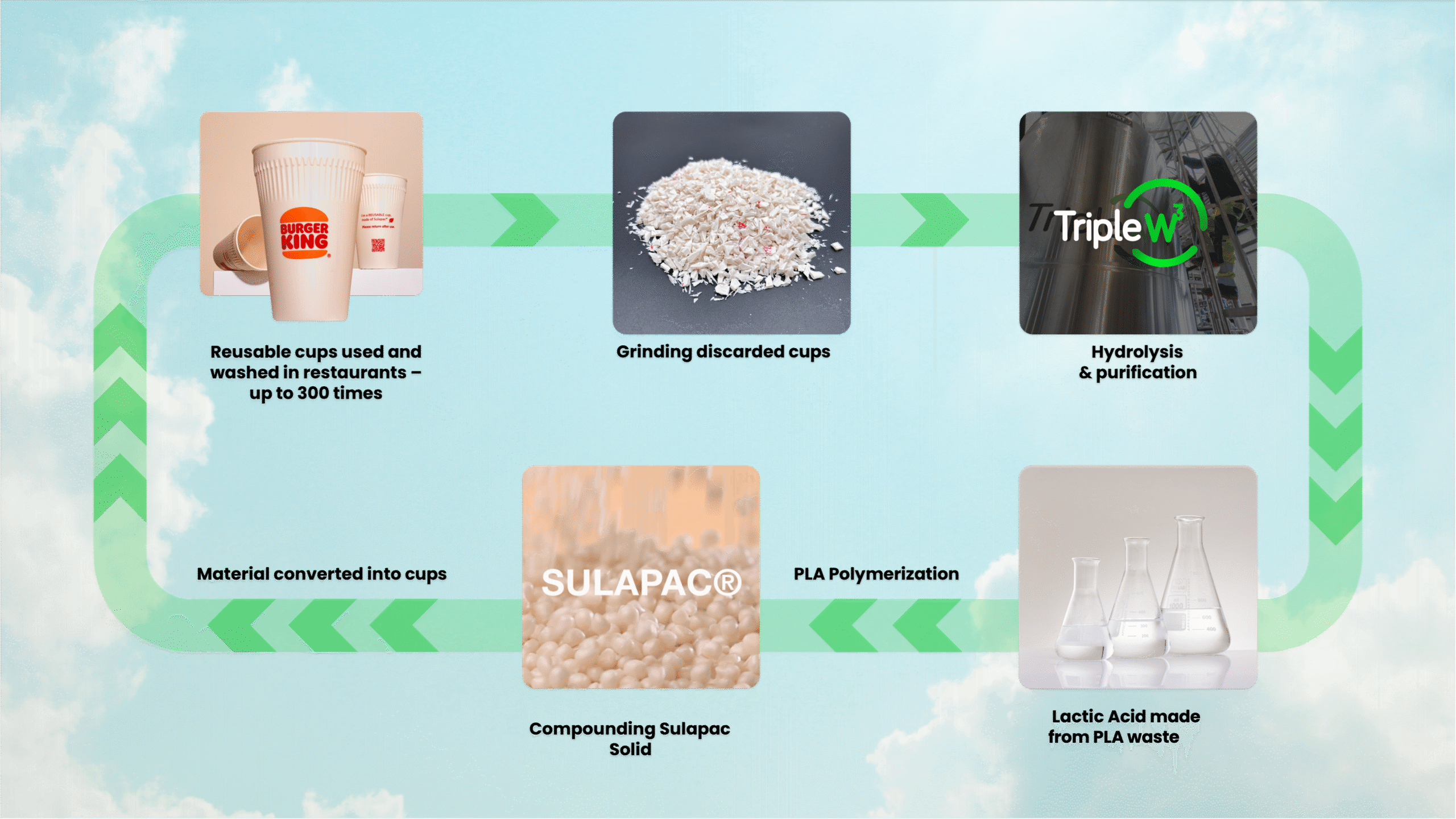

Driven by legislative pressure and growing environmental awareness, quick service restaurants, event organizers, and airlines alike, are turning into reusable tableware and packaging. TripleW and Sulapac present a forward-thinking solution: a biobased cup that is not only reusable but also, through a closed-loop recycling system, continuously serves as raw material.

ANTWERP / HELSINKI, 21 November 2025

TripleW, a Belgian innovator in circular biochemistry based in the Antwerp region, has partnered with Finnish Sulapac, a pioneer in sustainable plastic alternatives, to close the loop for good. Their closed-loop pilot demonstrates that reusable cups made from Sulapac Solid – a 100% bio-based and biodegradable material – can be chemically recycled commercially. The innovative upcycling system eliminates the need for fossil-based materials, delivers long-term cost savings and perfectly aligns with the European Union’s circularity goals.

“This is an important milestone for the EU’s Bioeconomy Strategy, we eliminate single use plastics, we increase resource-efficiency by using biological resources and our clients can benefit from going circular,” says Tal Shapira, CEO of TripleW.

The pilot also shows that the transition from single-use to reusable cups can be achieved in a circular manner without relying on fossil-based plastics.

“It’s remarkable that one doesn’t have to choose between biobased or recyclable packaging – you can have both, also when it comes to reusables,” says Dr. Heidi Peltola, Chief Product Officer at Sulapac.

A groundbreaking material innovation

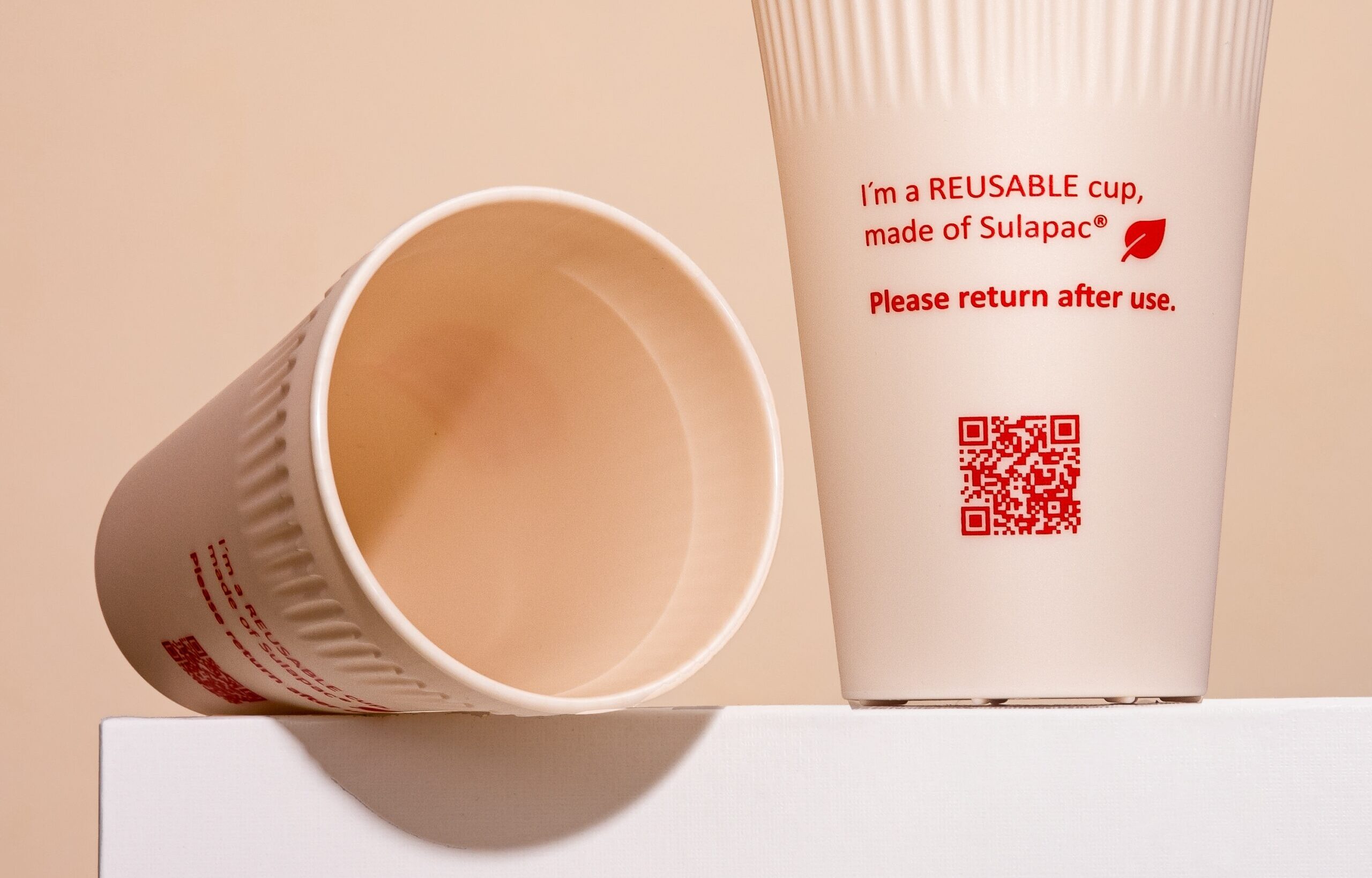

Sulapac’s solution for reusable cups, the 100% biobased and dishwasher-proof Sulapac Solid material, combines a premium ceramic-like appearance with exceptional durability. Thanks to its compatibility with standard plastic production processes and a composition designed for repeated use in demanding environments such as airplanes, cruise ships, and quick-service restaurants, Sulapac Solid offers a sustainable alternative to oil-based plastics at scale.

Break down and rebuild, the beauty of polymer-to-polymer recycling

TripleW’s state-of-the art recycling technology further amplifies the environmental benefits of renewable materials and reuse. In the pilot, used Sulapac Solid cups were collected, grinded and broken down via hydrolysis into their building blocks, including lactic acid. Lactic acid can be used, for example in personal care and pharmaceutical products, or it can be transformed back into a food-grade biopolymer. This energy- efficient polymer-to-polymer recycling process ensures the material can be reused repeatedly, eliminating waste and quality degradation.

Together with Sulapac, we’re showing that biobased and compostable materials like PLA-based compounds are not just sustainable alternatives – they can be truly circular,” says Shapira. “Our unique closed-loop model ensures every cup used on a plane or cruise ship can return as a new product, again and again. The chemical upcycling scaleup utilizing the Sulapac cups, resulted in full recovery of the lactic acid – building block of PLA,” concludes Shapira.

From closed-loop to mainstream

TripleW and Sulapac welcome companies from the hospitality business, events, and passenger transport industries across Europe to take advantage of the one-of-a-kind closed-loop system. The plan is to ambitiously grow the volumes of Sulapac Solid collected and recycled through TripleW’s platform during the following years.

“This partnership is a tangible step toward a future where high-performance sustainable materials like Sulapac Solid circulate just like traditional plastics – but without the environmental burden,” concludes Dr. Peltola.

Beyond the environmental impact, the closed-loop model developed by TripleW and Sulapac brings clear economic and strategic advantages. It reduces raw material and logistics costs, stabilizes supply chains, and shields companies from rising compliance burdens under EU legislation.

“Our approach is fully aligned with key European policies – from the Green Deal and the Circular Economy Action Plan to the upcoming Packaging and Packaging Waste Regulation. It exemplifies how circular bioeconomy innovations can position Europe as a leader in achieving circularity, reinforce industrial competitiveness, and offer scalable alternatives to fossil-based packaging,” adds Tal Shapira.

Further information:

Noora Nyländen

Marketing & Communications, Sulapac Ltd

+358 40 849 5286 – noora.nylanden@sulapac.com

Jeremi Van den Berghe

Communications, TripleW NV

+32 486 89 50 99 – jeremi@growth-inc.be

TripleW is a Belgian company driving the circular economy by transforming biobased and biodegradable materials, particularly PLA and lactic acid-based plastics, into new value streams. Through the development of local, closed-loop recycling systems, TripleW helps organizations reduce waste, lower their carbon footprint, and unlock the full potential of sustainable materials.

Sulapac Ltd is an award-winning material innovation company addressing the global plastic crisis. By replacing conventional plastic with sustainable, beautiful, and functional Sulapac materials, companies can reduce their carbon footprint, eliminate microplastic pollution, and advance the circular economy. Founded by three scientists in 2016, the Helsinki-based company serves customers across various industries on three continents. Investors behind Sulapac®, the patented material innovation, include CHANEL and Lifeline Ventures.