Scanfill and Sulapac push the green transition in packaging

Scanfill presents foil made of biobased and compostable Sulapac material, claiming a key position in the green transition of the European packaging industry. Packaging manufacturers can now replace conventional oil-based plastic in their thermoforming processes with an eco-friendly alternative – while continuing ‘business as usual’.

YSTAD / HELSINKI, 26 June 2025

Scanfill, a knowledge-based company that develops and produces world-class packaging materials, and Sulapac, a pioneer in bio-based, biodegradable plastic alternatives, have joined forces to help thermoformers across Europe meet their customers’ increasing sustainability requirements while preserving the integrity of both product quality and manufacturing performance.

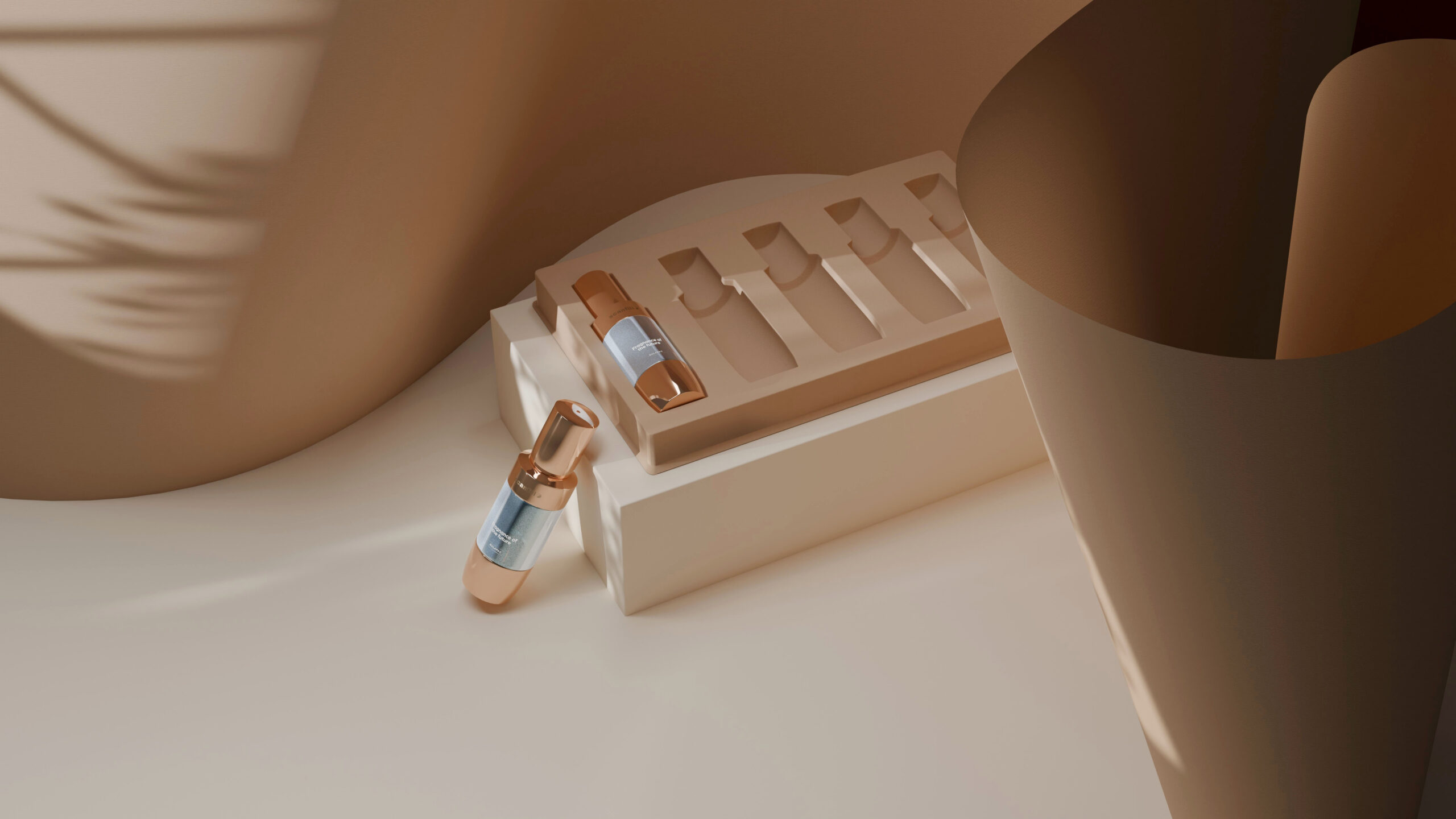

The Degrafoil Flow 1.7 by Scanfill is made of Sulapac Flow 1.7 wood-composite and is used in thermoforming machines as a direct replacement for conventional plastic foils. Sulapac Flow 1.7 combines the functionality of plastic with the advantages of fibrous materials. It is certified industrially compostable and due to its high bio-based content, it can significantly reduce the packaging’s carbon footprint compared to conventional plastics like PET.

Final products made of Flow 1.7 have a smooth, fiber-like surface that feels distinct from conventional plastic. The possibilities for color are nearly limitless. In terms of scratch resistance and durability, Degrafoil Flow 1.7 is comparable to traditional plastic.

“Customers value Flow 1.7 for its uncompromising nature,” summarizes Niklas Linde, Sales at Scanfill.

Accessible sustainability meets easy processability and consistent quality

Consistent quality and easy processability in thermoforming, were must-have features for the new material – and something that sets Sulapac Flow apart from competitors.

“For a long time, we’ve wanted to include a compostable alternative in our portfolio, but only Sulapac managed to meet our quality requirements,” says Karl Banke, Sustainability Specialist & Technical Support at Scanfill. “With Degrafoil Flow 1.7, our clients can respond to brand owners’ increasing demand for renewable content and reduced carbon footprint – while continuing business as usual”.

“Sulapac always aims to make sustainability an easy choice. That way, we can ensure our innovations spread widely and create meaningful impact,” explains Juho Luukkanen, Sales Director at Sulapac. “Together with Scanfill, which has a broad customer base and strong sales capabilities across Europe, we can accelerate towards that goal.”

Degrafoil Flow 1.7 is produced at Scanfill’s facility in southern Sweden following the requirements for food contact materials. The first packaging solutions powered by Sulapac and Scanfill are already on the market.

Further information:

Noora Nyländen

Marketing & Communications, Sulapac Ltd

+358 40 849 5286 – noora.nylanden@sulapac.com

Niklas Linde

Sales, Scanfill AB

+46 411 797 49 – niklas.linde@scanfill.se

Scanfill AB develops and produces world-class packaging materials. Its expertise lies in foil extrusion for thermoformed packaging, tailored to each customer’s individual requirements. Based in southern Sweden, Scanfill is part of the Polykemi Group, which has been delivering customized plastic compounds worldwide since 1968.

Sulapac Ltd is an award-winning material innovation company addressing the global plastic crisis. By replacing conventional plastic with sustainable, beautiful, and functional Sulapac materials, companies can reduce their carbon footprint, eliminate microplastic pollution, and advance the circular economy. Founded by three scientists in 2016, the Helsinki-based company serves customers across various industries on three continents. Investors behind Sulapac®, the patented material innovation, include CHANEL, Lifeline Ventures, and Sky Ocean Ventures.