Sustainable thermoformed packaging – create packaging inserts for applications from board games to beauty

Thermoformed plastic keeps many familiar products organised. Whether it’s holding board game pieces in place inside the package, supporting cosmetic items in a gift set or keeping beauty testers aligned on the retail counter, thermoformed plastic carries a lot of responsibility. It also carries a footprint, usually a fossil-based one. The good news is that in many cases, conventional plastic can now be replaced with a bio-based material that has a much smaller environmental impact.

To understand what adopting a bio-based theroforming material means in practice, let’s look at three common applications where sustainable thermoforming has already been tried and tested.

Thermoformed board game inserts

Open a game of Monopoly and you will find a thermoformed plastic insert holding the money, cards and tiny tokens in place. These inserts remain in use for years, or even decades, often with tiny fingers lifting and touching the piece repeatedly.

Conventional plastic has long been the material of choice for thermoformed packaging inserts, because it keeps its shape even long after everything around it has aged. How many of us have an old board game at home where the cardboard box is worn out and barely holding together, while the decades-old plastic insert inside looks almost untouched?

Calling all board game manufacturers to take action

Many brands want to move away from fossil-based thermoformed packaging, but conventional plastic has kept a steady grip on the market. Plastic is inexpensive, easy to manufacture at scale and supported by a mature supply chain. This combination has made it difficult to replace. The most common sustainable alternatives still fall short in functionality and cost-efficiency.

Our solution is a high performing wood-composite Sulapac Flow 1.7 that is created for thermoforming. Made from upcycled wood flour and biodegradable biopolymers, it behaves much like conventional plastic but without the high carbon footprint. It doesn’t get scratchy like molded pulp, it’s durable, and moist resistant, and hence works in applications where fossil-based plastic has traditionally been the only option.

Sulapac Flow 1.7 runs on standard thermoforming equipment and is supplied through established sheet producers, so adoption is cost-efficient and straightforward for both brands and manufacturers.

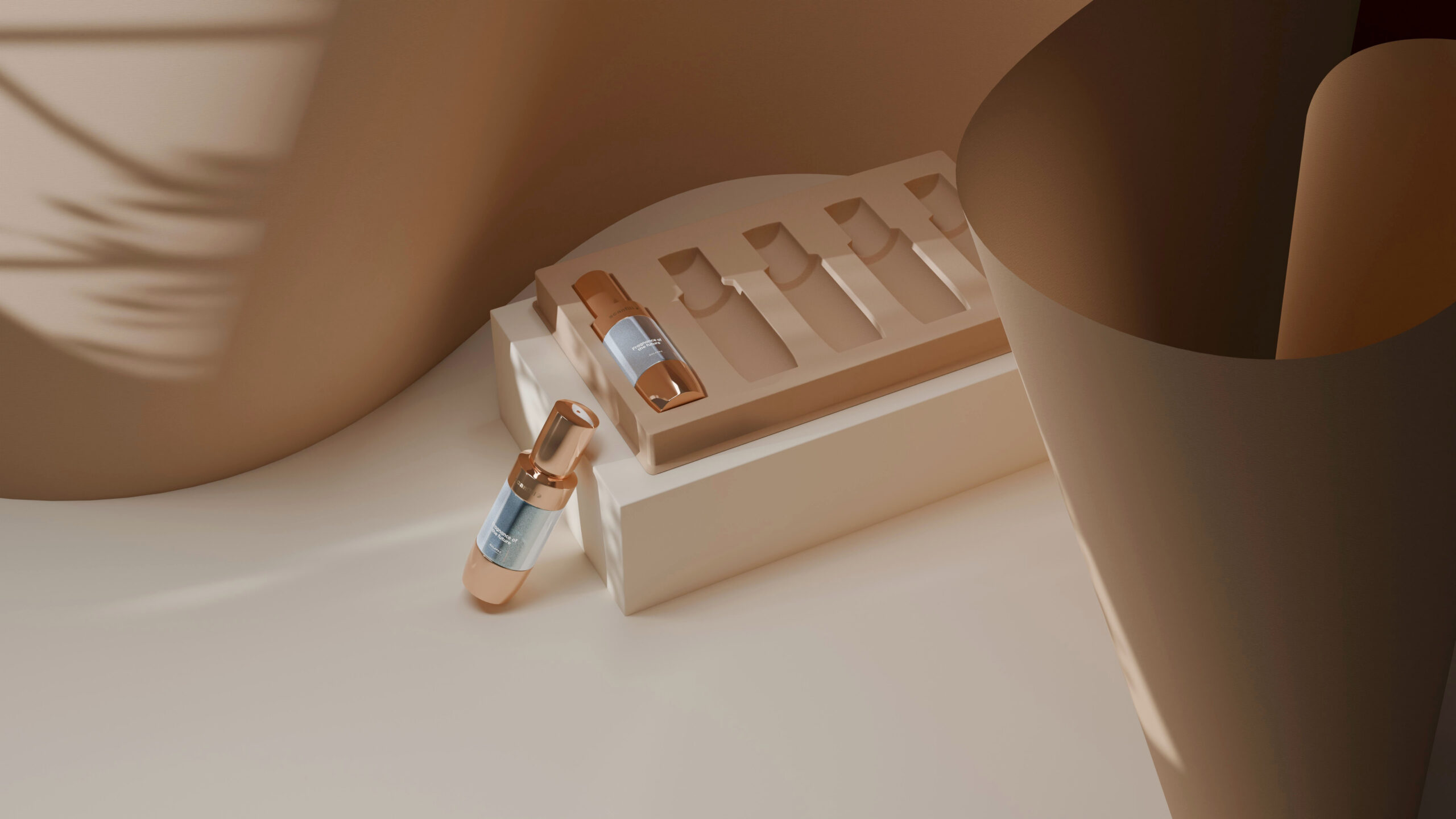

Thermoformed cosmetic trays and inserts

Cosmetic packaging places high demands on inserts. It often contains products in different shapes and sizes, such as tubes, jars, palettes and tools. The insert needs to hold each item firmly in place during transport, maintain a polished look when the customer opens the box and support the brand’s image through its decorative elements.

While many cosmetic brands already use sustainable materials for their outer packaging, the thermoformed insert is often made from fossil-based plastic.

When looking for sustainable thermoformed packaging alternatives, cardboard is usually the first option considered. It does, however, come with many design limitations. Decorative elements need to be printed separately, which adds an extra step to the production process. Folded structures also make it difficult to create clean, sculpted shapes.

Formed fibre, on the other hand, is easier to decorate and customise, but it can release small fibres on smooth cosmetic bottles and make them look dusty. There are high-end molded pulp solutions but they typically come with a heafty price tag.

Sulapac Flow 1.7 delivers functional, premium-feeling packaging inserts for cosmetic sets

Sulapac Flow 1.7 offers design freedom that cardboard and formed fibre can’t provide. Intricate shapes and decorative elements can be molded directly into the insert, enabling both seasonal packaging and fast production cycles.

The material can also be colour-matched to brand palettes. It has a refined, fibre-like quality that looks premium without the synthetic look of conventional plastic.

Thermoformed plastic retail displays and tester trays

Tester trays are among the most used items in a beauty store. To put that into perspective, Sephora’s flagship store on the Champs-Élysées has an estimated 10,000 visitors each day. This means a single tester can be picked up, tested and put back hundreds of times during the day. The tray needs to keep products aligned and within easy reach, and it must withstand frequent wiping with chemicals used in daily store maintenance. If a display requires extreme durability, or a glossier finish, bio-based injection molding materials such as Sulapac Luxe Flex or Sulapac Solid are the perfect fit.

Stores also use thermoformed display elements to highlight launches or seasonal campaigns. These pieces help brands stand out at the point of sale, so they need to keep their premium appearance throughout the campaign. Thermoformed plastic enables creating precise shapes and smooth surfaces, and it has the durability needed in busy retail environments.

Once a campaign ends, these components are typically discarded, which adds to the overall material footprint of visual merchandising, especially when the tester trays and displays are made from fossil-based plastics.

The same qualities that make Sulapac Flow 1.7 ideal for inserts also benefit in-store solutions. The material can be thermoformed into decorative or short-run pieces without burdening the environment excessively. It can also be used in both 3D printing and sublimation printing, which allows colours and graphics to be embedded directly into the material.

The hidden packaging component with a big potential

Thermoformed inserts often go unnoticed, yet they play a major role in how products are protected and experienced. They also carry a heavy environmental footprint, simply because they are used so widely and still made from fossil-based plastics. With bio-based thermoforming, renewable materials can now be used in applications where conventional plastic once felt irreplaceable.

Want to know more? We’re happy to help you explore what’s possible. Let’s talk.