Thermoforming with Sulapac Flow 1.7 – Complete beginner’s guide

Sulapac Flow 1.7 is a bio-based, biodegradable thermoforming material that delivers the performance of conventional plastics while reducing CO2 emissions and eliminating microplastic pollution. Designed as a drop-in solution for thermoforming manufacturers, the material delivers premium aesthetics and excellent processability without requiring new equipment investments. This comprehensive guide answers some of the most frequently asked questions about the properties, processing parameters, applications, and sustainability benefits of Sulapac Flow 1.7—in other words everything you need to know to implement this innovative thermoforming solution in your production.

1. Applications

What are the typical applications for Sulapac Flow 1.7?

Sulapac Flow 1.7 can be used in thermoforming as a replacement for PS (polystyrene), PP (polypropylene), and PLA (polylactic acid) for example. The material is ideal for producing packaging inserts and product trays, retail displays, drinking cups and lids, food containers, cake trays, and more.

What types of production lines and processes is it compatible with?

Sulapac Flow 1.7 is suitable for both in-line thermoforming and offline processes where sheets are formed separately. It performs well in both light and heavy gauge applications.

2. Material composition

What is Sulapac Flow 1.7 made of?

Sulapac Flow 1.7 combines biodegradable polymers with upcycled wood flour. The wood is sourced from sawmill side streams and originates from sustainably managed Northern European forests.

How much wood fiber does Sulapac Flow 1.7 contain?

The material contains approximately 20% wood-based content.

What is the natural color of Sulapac Flow 1.7?

The natural color of Sulapac Flow 1.7 is a light beige, resulting from its wood content.

Can Sulapac Flow 1.7 be colored?

Yes, Sulapac Flow 1.7 can be colored just like other thermoplastics. However, due to the material’s wood content, it naturally has a light beige tone. This means that transparent products are not possible to achieve, and any desired color tone must be matched separately.

Is a transparent grade of Sulapac Flow 1.7 available?

No, Sulapac Flow 1.7 is not available in a transparent grade.

3. Starting production

Is Sulapac Flow 1.7 easy to implement in existing thermoforming production lines?

Yes. Sulapac Flow 1.7 is a drop-in solution that doesn’t require any new equipment. In our tests conducted across various inline production systems, the transition from polystyrene to Sulapac Flow 1.7 has been smooth, requiring only minor, routine adjustments to extrusion and forming temperatures.

How does Sulapac Flow 1.7 perform in production compared to conventional plastics?

The material performs very similarly to conventional plastics. It runs efficiently through processes such as lip rolling without sticking. Production speeds are similar to those of polystyrene, and existing robotic systems using suction cups can handle the material effectively. Sulapac Flow 1.7 performs well in both vacuum and pressure forming.

4. Processing

What parameters should I use when thermoforming Sulapac Flow 1.7?

We recommend starting with PET processing parameters. If the material begins to overheat (indicated by a color change), try increasing the cycle time or lowering the heating temperature. The ideal surface temperature for the material is approximately 180°C.

Based on feedback from several thermoformers who have tested Sulapac Flow 1.7, the material behaves similarly to PET and is easy to process. Note that the reverse side of the sheet is slightly smoother, and either side of the sheet can be used depending on the desired finish.

Can I run Sulapac Flow 1.7 with existing tooling (PET, PS)? Are there any limitations?

Yes, you can. Sulapac Flow 1.7 is compatible with tooling designed for PET or PS. However, minor differences in shrinkage may occur. This should be taken into account when producing items that require high dimensional precision, such as click lids.

Is Sulapac Flow 1.7 sensitive to temperature fluctuations during processing?

Unlike many bio-based materials that require precise temperature control, the wood-based composition and natural insulating properties of Sulapac Flow 1.7 enable a wider processing window. The material also holds its shape well during heating and cooling, minimizing deformation and improving consistency.

Does Sulapac Flow 1.7 require special post-processing?

No, Sulapac Flow 1.7 does not require flocking or other post-treatments to achieve an appealing aesthetic. Many of our customers appreciate its natural appearance and choose to leave it uncovered. This eliminates an extra step in the production process, reducing overall costs.

5. Technical performance and properties

What are the Water Vapor Transmission Rate (WVTR) and Oxygen Transmission Rate (OTR) of Sulapac Flow 1.7?

WVTR (23 °C/85%) = 3.1 g/m²/day

OTR (23 °C/0%) = 11.2 cm³/m²/day

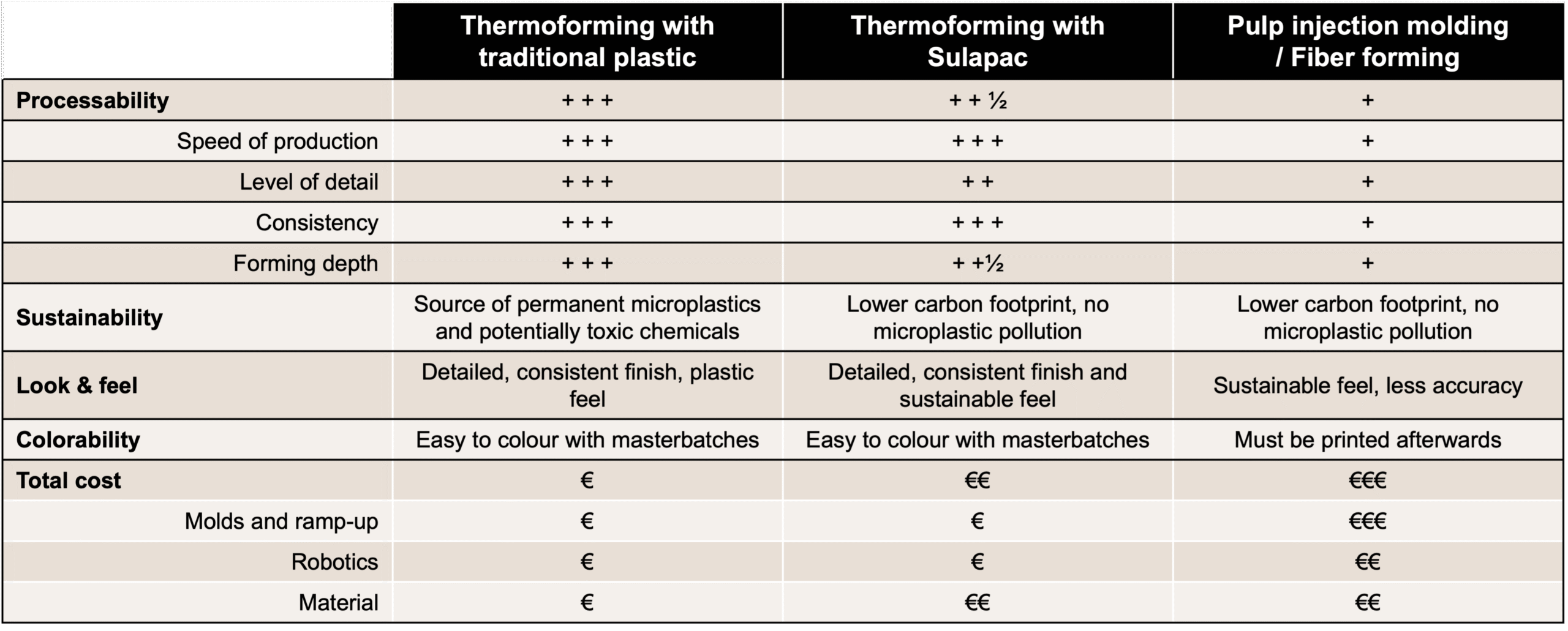

How does Sulapac Flow 1.7 compare to conventional plastics, molded pulp, or fiber forming?

Sulapac Flow 1.7 combines the technical and mechanical performance of conventional plastics with the environmental benefits of fiber-based solutions—without any of their common drawbacks. Unlike many fiber-based alternatives, Sulapac Flow 1.7 does not release loose particles during use.

Additionally, the material requires lower thermoforming temperatures than conventional plastics. Shorter heating times can result in up to 20% energy savings.

Is it possible to seal Sulapac Flow 1.7 to itself or to cardboard?

Yes. Sulapac Flow 1.7 has been successfully sealed both to itself and to cardboard using heat-sealing and RF sealing. Other common sealing methods used with conventional plastics are also applicable.

6. Sustainability and end-of-life

How should Sulapac Flow 1.7 be recycled?

Sulapac products and packaging can be disposed of with plastic waste. The materials do not disrupt the conventional plastic recycling process, as they can be separated from mixed waste using standard sorting methods, such as near-infrared technology (NIR). Their current recycling mark is 7 (Other plastics).

The growing presence of biodegradable materials in the plastic waste stream is being monitored, encouraging waste management companies to invest in dedicated sorting infrastructure. This will support the large-scale recycling of Sulapac materials and other biodegradables in the future.

Recycling bio-based, biodegradable materials is the most effective way to keep carbon in the loop, conserve natural resources, and minimize CO2 emissions. However, in specific cases, industrial composting may be a more suitable end-of-life option for Sulapac Flow 1.7, which is certified as industrially compostable by BPI and Seedling.

Can leftover Sulapac Flow 1.7 material be reused in extrusion?

Yes. Our preferred partners can purchase the skeletal or scrap waste from the thermoforming process. The material can then be reused as post-industrial feedstock in the extrusion process.

Does Sulapac Flow 1.7 leave behind any permanent microplastics?

No. Sulapac materials are fully biodegradable and can be broken down by naturally occurring microorganisms. They biodegrade into CO2, water, and biomass without leaving behind permanent microplastics.

This is confirmed through third-party testing based on the ASTM D6691 standard, which demonstrates that naturally occurring marine microorganisms can digest Sulapac materials.

For Sulapac Flow 1.7, 75.5% relative biodegradation into CO2 was measured after 420 days in a simulated marine environment test (ASTM D6691, 86°F / 30°C) using natural seawater. (Note: Not considered biodegradable in California.)

How fast does Sulapac Flow 1.7 biodegrade?

Sulapac Flow 1.7 biodegrades as fast as, or even faster than, natural materials such as tree leaves when placed in the same environment and when the items are of similar shape and size.

In an industrial composting facility, the material disintegrates within 12 weeks, in line with the EN 13432 standard (which requires that no more than 10% of the original dry weight remains on a 2 mm fraction sieve after composting).

Sulapac Flow 1.7 has been certified as industrially compostable up to a thickness of 910 μm by both BPI (ASTM D6400) and Seedling (EN 13423 and ASTM D6400).

Is Sulapac Flow 1.7 free from PFAS?

Yes. The material has been tested for per-and polyfluoroalkyl substances (PFAS) by an independent ISO/IEC 17025-certified laboratory using the CEN/TS 15968 test method. No PFAS compounds were detected.

Is Sulapac Flow 1.7 safe for the environment?

Yes. Sulapac Flow 1.7 has passed EN13432 and ASTM D6400 ecotoxicity tests conducted by a third-party laboratory. It has also been tested and confirmed to be free from PFAS.

Additionally, the material has successfully passed the Daphnia magna plankton toxicity test (according to OPPTS 850.1010 and OECD 202), also carried out by a third-party laboratory. The results show that the material’s degradation products are non-toxic and have no harmful effects on plankton in the marine ecosystem.

7. Compliance and safety

Is Sulapac Flow 1.7 compliant with food contact regulations (FDA/EU)?

Yes. Sulapac Flow 1.7 complies with both FDA and EU food contact regulations for all food types. However, specific restrictions and conditions of use apply. Please refer to the relevant Declaration of Compliance for further information.

Does Sulapac Flow 1.7 pass organoleptic tests?

Sulapac Flow 1.7 has passed organoleptic tests in both short- and long-term use, depending on the food type. However, due to the material’s natural wood content, we recommend that you conduct your own organoleptic testing with the intended end product to ensure suitability.

8. Aesthetics and design

Can Sulapac Flow 1.7 be customized for branding purposes?

Yes, Sulapac Flow 1.7 offers exceptional customization options, making it an ideal choice for innovative branding. Its features include:

– Vibrant color options: You can achieve virtually any color with master batches, just like with conventional plastics.

– Intricate details and surface structures: Unlike fiber- or cardboard-based alternatives, Sulapac Flow 1.7 allows intricate details to be directly molded into the product, ensuring uniformity and a seamless production process.

– Natural look and feel: The material’s pleasing appearance eliminates the need for post-processing.

9. Availability and specifications

Where can I buy Sulapac Flow 1.7 sheets?

Sulapac Flow 1.7 sheets are available through our preferred partners: Scanfill in Europe and Primex in the United States. If your production takes place in Asia, please contact us directly for guidance.

What thickness options and dimensions are available?

There are no material-related limitations on the maximum sheet thickness of Sulapac Flow 1.7. Our partners can produce sheets starting from 300 µm, and they can be customized to your desired thickness and width. So far, sheets up to 8 mm thick have been successfully produced.

10. Regulatory and future trends

How does Sulapac Flow 1.7 align with packaging regulations?

The EU’s Packaging and Packaging Waste Regulation (PPWR) aims to advance packaging recyclability, increase the use of recycled content, and reduce dependence on single-use plastics. Under the regulation, bio-based and biodegradable thermoplastic materials are considered recyclable provided they meet specific design for recycling criteria. This criteria is still under progress and we are contributing actively in the formatting through CEN working groups. A fact is that Sulapac Flow 1.7 can be mechanically recycled with existing technologies, and it can be sorted out from mixed waste streams with existing technologies like NIR. Sulapac Flow 1.7 material can also be manufactured with recycled biopolymers to support the recycled content targets and requirements.

Furthermore, Sulapac Flow 1.7 is industrially compostable providing a sustainable end-of-life option for certain cases in selected geographical regions.

Why choose Sulapac Flow?

Sulapac Flow 1.7 is the only thermoforming solution currently on the market that combines biodegradability, a high bio-based content, easy processability, and premium aesthetics while ensuring efficient production. Its credentials are backed by rigorous scientific testing and third-party certifications and Lean Six Sigma quality management methodology.

Made from primarily renewable raw materials and incorporating forest industry side streams, Sulapac Flow 1.7 advances the circular bioeconomy. Additionally, it helps eliminate microplastic pollution and reduce toxic waste, both of which pose significant environmental and health risks.

In summary, Sulapac Flow 1.7 offers manufacturers a practical and easy step towards reducing plastic waste and transitioning to a more sustainable, circular economy.

Sulapac Flow 1.7 represents a new generation of thermoforming materials that combine production efficiency with environmental responsibility. Designed to run on existing production lines, it offers a high-performance, drop-in alternative to fossil-based plastics—without compromising on aesthetics or processability. Choosing Sulapac Flow 1.7 is an investment in the future of responsible thermoforming.

Want to find out more? For further guidance, reach out to our experts today!